Tailings Management Facility

Ambatovy generates tailings during nickel extraction at the process plant which is deposited at the Tailings Management Facility (TMF) via an 8 km pipeline, located west of the Process Plant.

Our TMF currently comprises:

- Two tailings deposition basins, namely the TMF 1 (North Basin) and the TMF 2 (South Basin):

- The North Basin comprises of the North Starter Dam 52 mamsl, with the remaining perimeter at 56 mamsl

- The South Basin comprises 12 Dams constructed to elevation 46 mamsl,

- The North and South Basin are connected via a decant system.

- A Valve Station located centrally between the North and South Basins along the eastern side into which the Tailings are pumped from the process plant;

- Two tailings slurry distribution pipelines feed the deposition basins from the Valve Station into the North or South Basin;

- A reclaim barge is located in the South Basin and is connected to the Ocean Outfall Line;

- An emergency spillway in the South Basin on the south-western side;

- Nine Sediment Control Dams (SCD’s), three below the North starter Dam and six below the South Basin dams;

- One permanent pump back facility from the main North Basin SCD and five on the South Basin SCD’s;

- Monitoring and interception boreholes in the buffer zone.

- Fifteen Seepage Collection Systems (SCS) from which water is pumped back into the basins;

- Numerous access roads.

Commitment to the Implementation of the GISTM

The Global Industry Standard on Tailings Management (GISTM) was developed by the independent Global Tailings Review following the Brumadinho tailings disaster. The Standard strives for zero harm to people and the environment with zero tolerance for human fatality by prioritizing safety of the Tailings Management Facilities through all phases of the mine lifecycle.

ICMM members are committed that all facilities with ‘Extreme’ or ‘Very high’ potential consequences will be in conformance with the Standard by August 2023, and all other facilities by August 2025.

Ambatovy, although not a member of the ICMM, is committed to fully implementing GISTM for its “Extreme” rated TMF and achieved substantial compliance by August 2023. We will continue to work on achieving full compliance

How We Manage Tailings

Our TMF is managed and monitored 24/7 by a multidisciplinary team led by the TMF Manager who is appointed since October 2021 as Responsible Tailings Facility Engineer (RTFE). Our team has continuous access to independent consulting engineering advice to comply with local regulations, permits, and international good practice standards throughout the facility life cycle. Tailings management is included in the Enterprise Risk Register since project commissioning.

An independent Engineer of Record (EoR) carries out quarterly inspections and audits. The EoR provides QA/QC during dam construction activity. In addition, an Independent Tailings Review Board (ITRB) inspects the facility on an annual basis, reviewing operational reports, policies and procedures and issue a yearly report. The facility is also inspected annually by the Malagasy government regulator, the O.N.E.

A dam breach analysis has been developed and is updated whenever there is a material change in the TMF and the resulting inundation mapping has been used in the development of an emergency preparedness and response plan, drawn up in consultation with Community Relations and Environment departments, local authorities and the national emergency response organization (BNGRC). The plan has been communicated to downstream villages and evacuation drills are held yearly during which villagers make their way to pre-determined assembly points on nearby hills, and remain there until the ‘all clear’ signal is given. In addition, a regular environmental monitoring programme is carried out, part of which comprises daily monitoring of surface- and ground-water quality.

Approach to Tailings Facility Risk Management

As part of an effective Tailings Management System (TMS), four key critical control areas are integrated for the management of our Tailings Management Facility:

- TMF Integrity

- Operations, Maintenance and Surveillance

- Emergency Preparedness and Response Plan

- Governance and Assurance

Within each of these areas are specific and critical controls with appropriate reporting systems. It is also noteworthy that these control areas are not isolated from one another, but all are interconnected parts of the TMS.

TMF integrity composed of all elements from site characterization to closure designs, captured in deliverables such as design reports, construction recording reports, quarterly audit reports and annual performance report, and so forth.

TMF integrity controls are underpinned by the implementation of good engineering practices across the facility life cycle. TMF integrity also captures more than just structural integrity and includes environmental integrity, embracing all technical disciplines including geotechnical, hydrology, hydrogeology and geochemistry.

Maintaining TMF integrity requires ongoing focus on appropriate engineering design, quality construction, operating discipline and effective governance.

Central to our approach is the recognition that maintaining TMF integrity is an ongoing process of continuous assessment that needs to be maintained for the life cycle of the facility, including post closure.

Operation, surveillance, maintenance, effective monitoring and review practices must operate in line with TMF design requirements and are quality assured and controlled to ensure the TMF is functioning as intended.

Our mandatory performance requirements for TMF are designed to ensure data and records are maintained and accessible at all stages of the TMF life cycle.

Surveillance

Given TMF is a dynamic structure, effective monitoring, surveillance and review is central to ongoing facility integrity and governance. These processes span five dimensions with the specific details commensurate with the significance of the TMF:

- Monitoring systems – operating in real time or periodically

- Routine surveillance – undertaken by operational, geotechnical and survey teams

- Periodic TMF audits – undertaken quarterly by the Engineer of Record

- Independent Tailings Review Board audit – undertaken annually by an independent board of professional engineers reviewing aspects across both TMF integrity and governance

- Dam Safety Reviews (DSRs) – conducted every 5 years by an external third party led by an external qualified professional engineer with support and input from other technical specialists from fields such as hydrology, geotechnical, seismicity, geochemistry and mechanical.

While TMF integrity and operation, surveillance and maintenance elements of our approach aim to prevent TMF failure risk, the third key element is mitigation.

Therefore, a robust Emergency Preparedness and Response Plan (EPRP) has been developed and implemented for credible failure modes based on a dam break inundation study. The objective of the EPRP is to prevent, mitigate, or reduce impacts in the unlikely event that TMF failure was to occur.

Our approach to emergency response planning for our TMF is designed to be commensurate with the level of risk and includes:

- Defined roles and responsibilities of response teams

- Identifying and monitoring for conditions and thresholds that prompt preventive or remedial action

- Assessing and mapping the potential impacts from a hypothetical, significant failure including impacts to people, environment and infrastructure, regardless of probability

- Establishing procedures to assist operations personnel responding to emergency conditions at the TMF

- Plan training, testing, and updating guidelines to ensure uniformity across the organization.

- Engaging, testing and integrating our emergency response plans (ERP) with external authorities, including conducting coordinated annual drills to ensure readiness and transparency

- Engaging with community stakeholders to maintain a shared state of readiness

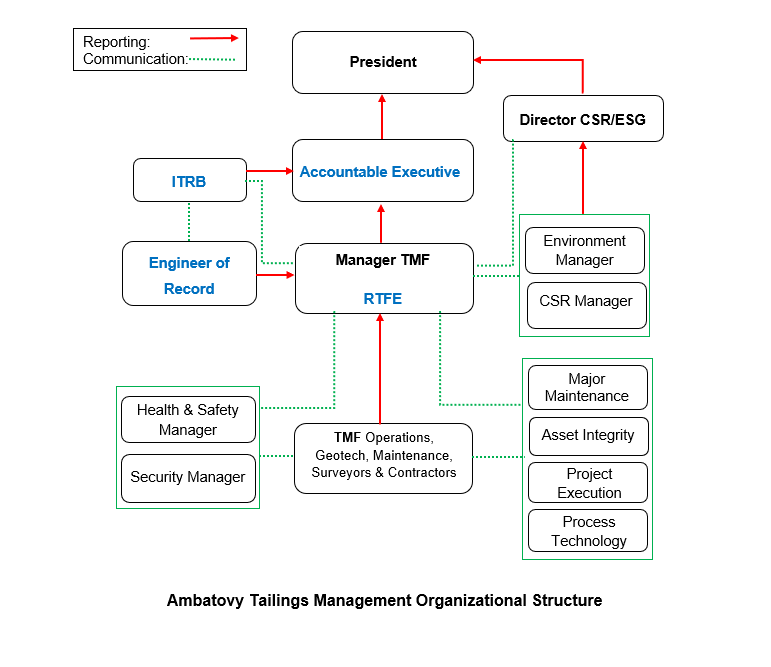

Ambatovy uses a governance structure based on three lines of defense (3-LoD) model for the management of its tailings facility. The 3-LoD model is a demonstrated strategy in effective risk management and control to ensure that there is adequate performance, support, review, and accountability throughout the TMF life cycle.

Under this model, the first line is comprised of TMF department team who actively manages the facility, led by the TMF Manager appointed as RTFE and a dedicated EoR serving as a partner with the RTFE to ensure safety of the facility. The role of the first LoD is to take the responsibility for the TMF and the associated work on site, owns, manages and oversees associated risks, and work with the second and third LoD on assurance activities or where specific guidance is required.

The RTFE is supported by corporate teams (environmental, social, maintenance, etc.) when required.

The second LoD includes independent assurance activities, including the ITRB and the periodic Dam Safety Review assurance activities that are led by the third LoD.

The third LoD is composed of the Accountable Executive who is directly answerable to the President, and communicates with the Executive Committee on matters related to tailings management. The third LoD is responsible for establishing policy and conducting independent assurance activities.

Our Tailings Management Organizational Structure is presented below.

Disclosure

Ambatovy developed a disclosure in response to the Investor Mining and Tailings Safety Initiative led by the Church of England Pensions Board and the Swedish Council on Ethics.

This disclosure provides an overview of our tailings management system, and how we manage risk; a description of updates to our approach following recent disasters; and main information relevant to our TMF to be published in the Global Tailings Portal, a public, searchable database with detailed information on more than 1,700 mine tailings dams around the world.

> Click Here to see Disclosure

For more information on our commitment to safe tailings management, emergency preparedness and response, recovery in the unlikely event of a failure and transparency refer to our Tailings Management Policy.

> Tailings Management Policy (English)

> Pôlitika Fitantanana ny Toeram-Panatobiana Ambin’Akora (Malagasy)